Danish Engineering Inc.

Precision CNC Machining Solutions

Precision Solutions Across Industries

From heavy engineering to pharmaceutical equipment, we deliver specialized machining solutions tailored to your industry's unique requirements

Heavy Engineering Industries

Advanced machining solutions for heavy-duty industrial machinery and equipment manufacturing

Reduced production time by 40% for a leading industrial machinery manufacturer

Components We Manufacture

+2 more components

Bearing Industries

Ultra-precision bearing components with tight tolerances for optimal performance

Manufactured 5000+ bearing rings with 99.8% first-pass quality rate

Components We Manufacture

+2 more components

Industrial Machine Manufacturers

Custom-engineered components for sophisticated manufacturing systems and automation

Partnered with 15+ machine tool manufacturers across Gujarat

Components We Manufacture

+2 more components

Packaging Industries

High-performance components for modern packaging machinery and automation systems

Enabled 30% faster packaging line speeds through precision components

Components We Manufacture

+2 more components

Pharma Machine Manufacturers

FDA-compliant precision machining for pharmaceutical manufacturing equipment

ISO-certified components for 10+ pharmaceutical equipment manufacturers

Components We Manufacture

+2 more components

Wind Turbine Components Industries

Large-scale precision components supporting renewable energy infrastructure

Supplied components for 50+ MW wind energy projects

Components We Manufacture

+2 more components

Pump & Valves Industries

Critical flow control components engineered for reliability and performance

Zero-defect record for critical valve components over 2 years

Components We Manufacture

+2 more components

Switchgear Industries

Precision electrical components for power distribution and control systems

Machined components for India's leading switchgear manufacturers

Components We Manufacture

+2 more components

Don't See Your Industry?

We work with diverse sectors and provide custom machining solutions for unique requirements. Contact us to discuss how we can support your specific industry needs.

Precision CNC Machining Services

Full-spectrum job work and component manufacturing with transparent pricing and guaranteed quality

CNC Turning Job Work

CNC TURNING ST-20 HAAS

High-precision CNC turning services for shafts, gears, and cylindrical components with exceptional accuracy

Key Use Cases

MATERIALS WE WORK WITH

CNC Turning Machine Job Work Service - Gear

CNC TURNING ST-20 HAAS

Precision CNC gear turning services for automotive, industrial, and power transmission applications

Key Use Cases

MATERIALS WE WORK WITH

Heavy CNC Turning Job Works Service

CNC TURNING ST-20 HAAS

Heavy-duty CNC turning for large shafts and industrial components requiring robust machining

Key Use Cases

MATERIALS WE WORK WITH

CNC Turning Job Work - Brass Components

CNC TURNING ST-20 HAAS

Precision brass component manufacturing for electrical, plumbing, and decorative applications

Key Use Cases

MATERIALS WE WORK WITH

CNC VTL VHSM VTC 1500 ATC

CNC VTL-VHSM VTC-1500 ATC

Soft & hard turning of bearing rings, hydraulic cylinder parts, large components up to 1650mm

Key Use Cases

MATERIALS WE WORK WITH

CNC SS Turning Job Work Service

CNC TURNING ST-20 HAAS

Specialized stainless steel CNC turning services for corrosion-resistant precision components

Key Use Cases

MATERIALS WE WORK WITH

Need a Custom Quote?

Upload your technical drawings and specifications. We'll respond within 24 hours with a detailed quotation.

Precision BeyondExpectations

Trusted CNC Manufacturing Since 1998

We are specialized in CNC Turning & CNC Milling precision job shop activities with modern factory premises, inspection facilities, design department, and strong commitment to innovation. Since 1998, we have been delivering precision machining solutions that enable our clients to achieve their manufacturing goals with confidence.

"Since 1998, our mission has been to deliver precision machining solutions that enable our clients to achieve their manufacturing goals with confidence and efficiency."

Mr. Nilay Shah

Founder & Managing Director

Our Manufacturing Capabilities:

Modern Manufacturing Facility

Manufacturing Floor

Meet Our Leadership

Driven by vision, guided by experience, committed to excellence

Mr. Nilay Shah

Executive Director

Mr. Nilay Shah

Executive Director & Mechanical Engineer

"Innovation and precision are not just our business goals — they are our commitment to every client we serve."

A mechanical engineer by profession, Mr. Nilay Shah brings 29+ years of fast-paced and success-oriented experience in precision engineering manufacturing. His considerable progress, unwavering commitment & strong vision continue to enable innovative breakthroughs that drive the company's progress towards tomorrow.

Quality Certifications

Our commitment to quality is validated by internationally recognized standards

ISO 9001:2015 Certified

Quality Management System

More Certifications

Additional quality accreditations and industry memberships

Our Journey of Excellence

Click on any milestone to explore our evolution and key achievements over the years

Company Founded

Danish Engineering Inc. established with a vision for precision manufacturing

Started as a small precision job shop with a commitment to quality and customer satisfaction.

First CNC Machine

Invested in state-of-the-art CNC equipment to enhance precision capabilities

Major investment in advanced CNC turning and milling equipment marked our technological advancement.

Facility Expansion

Expanded to modern factory premises with advanced inspection facilities

Moved to larger facility with comprehensive quality control and inspection capabilities.

Digital Innovation

Implemented cutting-edge technology and automation systems

Embraced Industry 4.0 with digital manufacturing processes and smart factory solutions.

Industry Leadership

Recognized as a trusted partner across multiple industrial sectors

Achieved recognition as a leading precision engineering partner serving diverse industries.

Ready to Experience Excellence?

Tour our state-of-the-art facility, meet our expert team, and see precision engineering in action. Let's discuss how we can bring your vision to life.

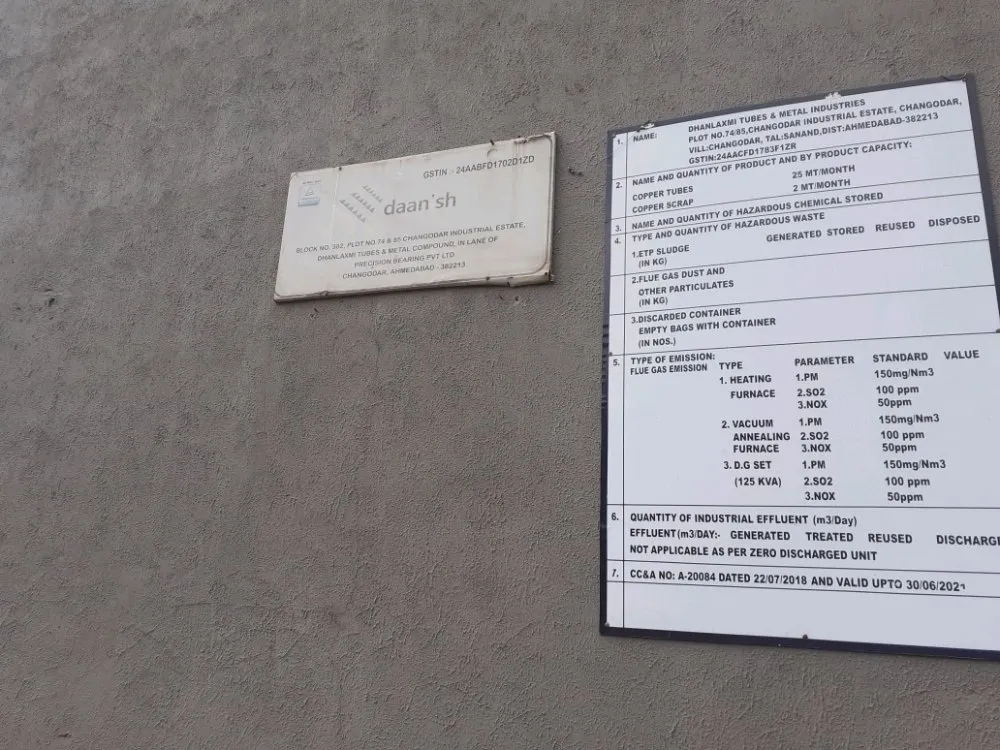

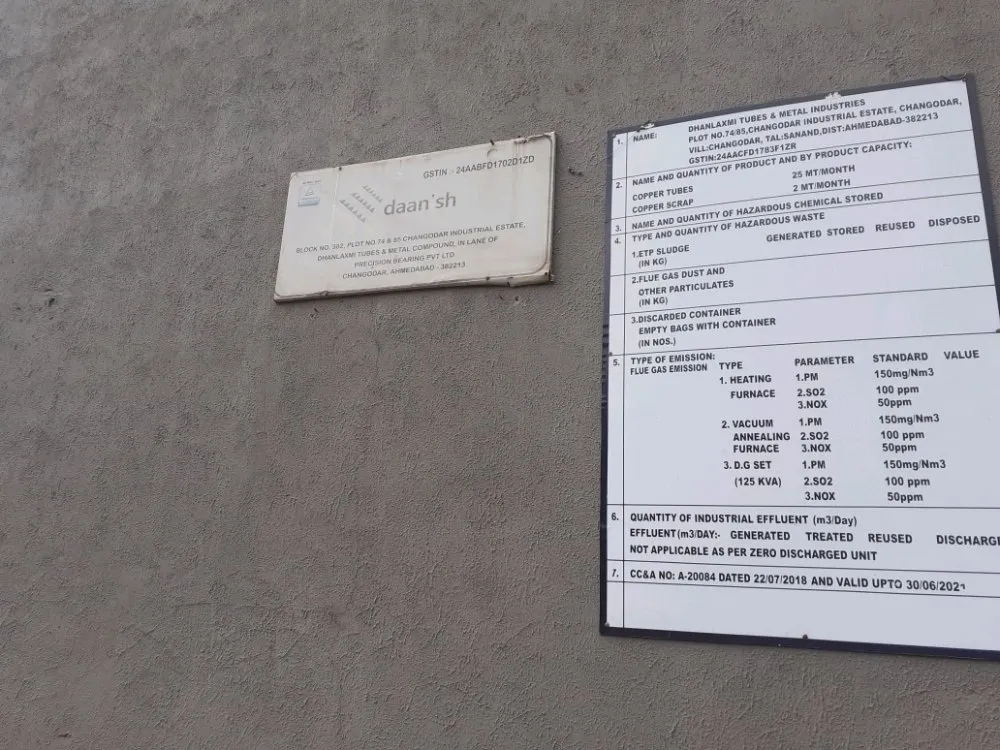

Visit Us

Block No 382, Changodar Industrial Estate, Changodar, Ahmedabad - 382213

Call Us

+91 98765 43210

Email Us

nilay@daanishengineering.in

Success Stories & Client Reviews

Real results and testimonials from industry leaders who trust Danish Engineering for precision, quality, and reliability.

Proven Results Across Industries

See how we've helped businesses achieve measurable success

Ambika Engineering

Required 1000+ bearing rings per month with ±0.002mm tolerance and ISO P5 precision class

Solution

Implemented dedicated VTL machining setup with automated quality inspection and just-in-time delivery

Jaydeep Kumar

Need for FDA-compliant stainless steel parts with Ra 0.8 surface finish for pharmaceutical tablet press

Solution

Specialized SS turning with validated processes and material traceability documentation

Bhupinder Singh

Complex gear components for heavy-duty gearbox requiring multi-axis machining

Solution

VMC 4-axis machining with comprehensive quality control and reverse engineering support

"Danish Engineering has consistently delivered precision components that exceed our quality standards. Their expertise in CNC machining is unmatched."

Quality

Delivery

Response

Rajesh Kumar

Chief Engineer

Turbine Dynamics Ltd.

Mumbai, Maharashtra • October 2024

Join Our Growing Family of Satisfied Clients

Experience the difference of working with a precision engineering partner committed to your success. Let's build something exceptional together.

Driven byQualityGuided byIntegrity

Where precision meets passion

Our mission and values shape every decision, driving us to deliver excellence that exceeds expectations in precision engineering and manufacturing solutions.

See Our Precision in Action

Watch how we transform raw materials into precision components

Our Mission

"To be the most successful and trusted resource for quality, reliable products and services that give customer delight."

Proven Track Record

Numbers that speak to our commitment to excellence and customer satisfaction.

Projects Completed

Successfully delivered precision engineering projects

On-Time Delivery

Consistent delivery within promised timelines

Customer Support

Round-the-clock technical assistance

Years Experience

Continuous growth and innovation

Our Core Values

The fundamental principles that guide our operations and define our commitment to excellence.

Trust

Reliability in Every Delivery

Building lasting relationships through reliability and consistent excellence in every project we undertake.

Integrity

Ethical Excellence Always

Maintaining the highest ethical standards in all our business practices and client interactions.

Transparency

Open Communication

Open communication and honest dealings that foster confidence and long-term partnerships.

Innovation

Cutting-Edge Solutions

Continuous innovation and adoption of cutting-edge technology to deliver superior results.

Join Us in Delivering Excellence

Ready to experience precision engineering that exceeds expectations? Let's build something exceptional together.

Frequently Asked Questions

Find answers to common questions about our CNC machining services, pricing, and processes

We welcome projects of all sizes! Most services have no minimum order quantity. For specialized services like Heavy Duty Lathe Work, we have minimum hour requirements. Prototype, small batch, and high-volume orders are all accommodated.

We work with a wide range of materials including all grades of stainless steel (SS304, SS316, SS316L, SS410), carbon steel, aluminum alloys, brass, copper, tool steel, cast iron, hardened steel, and exotic alloys. If you have a specific material requirement, please contact us.

Lead times vary by service: CNC Turning (3-7 days), VMC Work (2-5 days), VTL Machining (7-14 days), SS Turning (5-10 days). Rush orders can be accommodated. Contact us with your timeline requirements.

Simply upload your technical drawings (PDF, DWG, STEP files) through our quote form, or WhatsApp them to +91 98256 99180. We typically respond within 24 hours with a detailed quotation including pricing, lead time, and technical recommendations.

Yes! We offer competitive pricing for high-volume orders. Discounts are available for orders above 100 pieces or long-term contracts. Contact us to discuss your volume requirements.

We routinely achieve tolerances of ±0.001mm to ±0.005mm depending on the service and material. For ultra-precision applications, we can achieve ±0.001mm. Our ISO 9001:2015 certification ensures consistent quality.

Yes, we provide complete material traceability and test certificates for all materials used, particularly important for pharmaceutical, food-grade, and critical applications.

Absolutely! We offer reverse engineering services where we can work from sample parts to create technical drawings and manufacture components even without original drawings.

We are ISO 9001:2015 certified with comprehensive quality control including CMM inspection, surface finish testing, hardness testing, and dimensional verification. Every component is inspected before dispatch.

Yes, we ship to all locations across India. We have reliable logistics partners for safe and timely delivery. International shipping can also be arranged upon request.

Absolutely! We welcome facility visits and virtual tours. Please schedule an appointment by calling +91 98256 99180 or booking through our website.

We offer flexible payment terms based on order size and client relationship. For new clients, we typically work on advance payment or LC terms. Regular clients enjoy credit facilities. Contact us to discuss terms suitable for your business.

Still Have Questions?

Our team is here to help! Reach out via WhatsApp, phone, or email for personalized assistance with your project requirements.

Let's Engineer ExcellenceTogether

Ready to bring your precision engineering project to life? Contact us today to discuss your requirements and discover how we can help.

Call Us

+91 98256 99180

+91 81289 26363

Speak directly with our engineering team

Email Us

nilay@daanishengineering.in

Get detailed responses to your inquiries

Visit Us

Block No 382, Changodar Industrial Estate, Changodar, Ahmedabad - 382213

Tour our state-of-the-art facility

Business Hours

Mon - Fri: 8:00 AM - 6:00 PM

Sat: 8:00 AM - 2:00 PM

We are here when you need us

Send Us a Message

Our Location

Danish Engineering Inc.

Block No 382, Changodar Industrial Estate, Changodar, Ahmedabad - 382213

Quick Response Guarantee

We understand the importance of your projects. Our team responds to all inquiries within 24 hours, with detailed technical consultations available within 48 hours.